Technologies

Our Cutting-Edge Software Solutions

CAMM Metals has some of the latest and greatest in manufacturing software and equipment. To help our shop to meet the needs of a modern-day OEM, we have increased the technology we use on the floor to manufacture the products we make.

Our team invests in cutting-edge technology to enhance our operations. As a company, our ability to serve a growing customer base has increased due to the software solutions we’ve adopted in all areas of our business, from the offices to the shop floor.

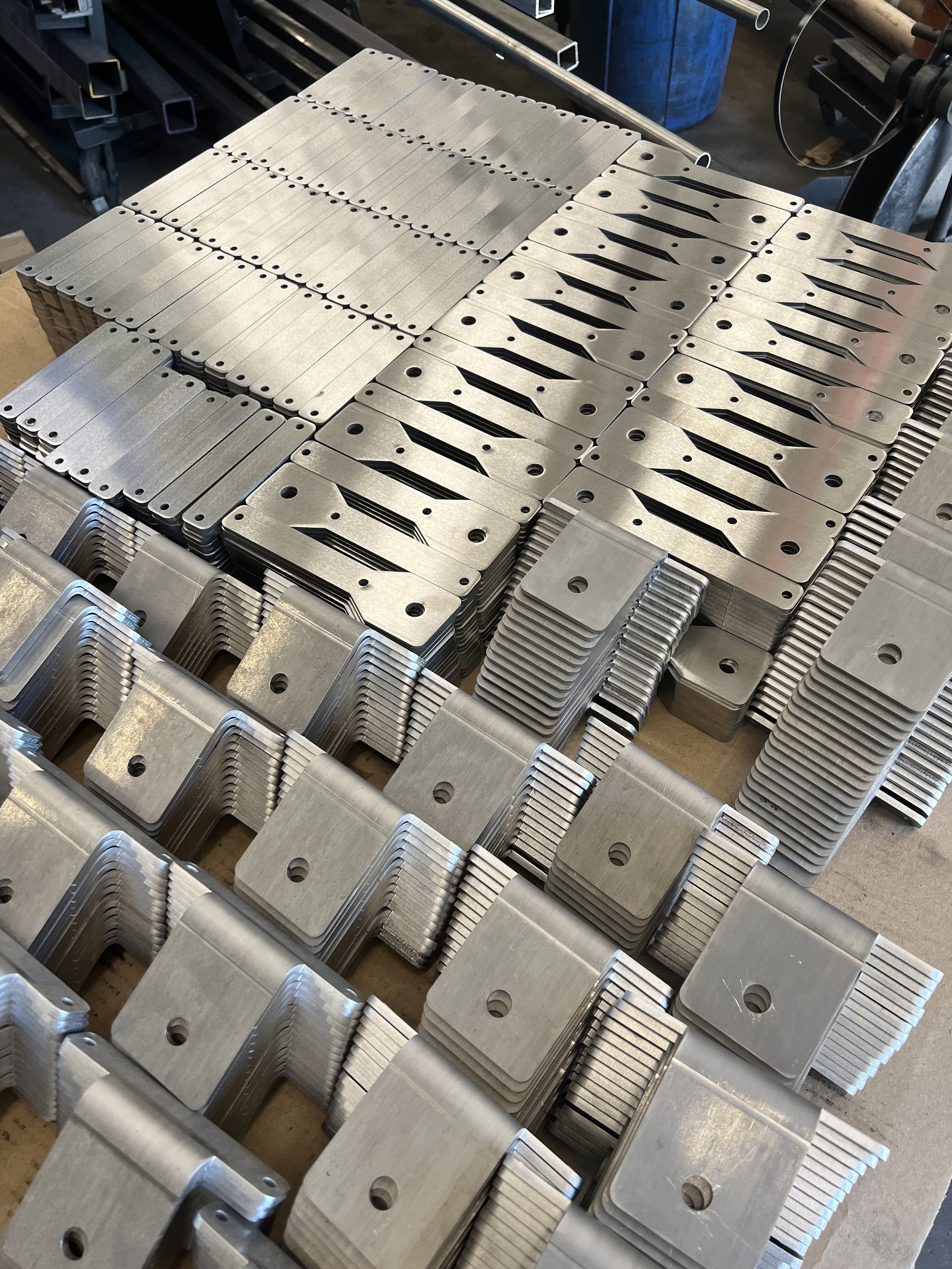

Modernizing Our Sheet Metal Fabrication Services

Accelerating and Enhancing Quoting with Paperless Parts

One of our software solutions that our customers interact with directly, Paperless Parts, has significantly impacted quoting at CAMM Metals. This tool offers a venue for our customers to submit requests for quotations. Our simple, secure form provides a single, centralized place to submit designs, models, and files related to a part. Its cloud-based system empowers our team to quote components with greater speed and accuracy than ever before. Additionally, it allows us to identify risks and discrepancies in drawings and models so we can respond proactively and swiftly.

Proactively Assessing Manufacturability with Engineering Software

We’ve invested in engineering software that sets our team up for success from the moment we receive an RFQ. When our team inspects parts in CAD, they can assess any manufacturing difficulties they might foresee and prevent them before we spearhead production. Once a job reaches the floor, we seldom experience any design issues, and we see hardly any delays in processing because of the full picture we obtain from the time we spend planning and engineering each job before it goes into production.

Making Data-Driven Decisions in Real Time with Fulcrum

Our team identified a need to meet customers’ schedule requirements and manufacturability considerations. To respond to the nuances of modern-day manufacturing, we invested in Fulcrum, an advanced could-based MRP system that offers transparency across our business. Through robust job tracking, our team can access real-time data that considers the big picture and intricate details. The platform’s automated production scheduling tool empowers us to increase throughput, and its live inventory tracking ensures we have all necessary materials at all times.

Connect with a Trusted Custom Metal Fabrication Shop

Partner with CAMM Metals for versatile sheet metal fabrication services. We’re your single-source supplier for sheet metal cutting, bending, fabricating, and welding services.