Waterjet

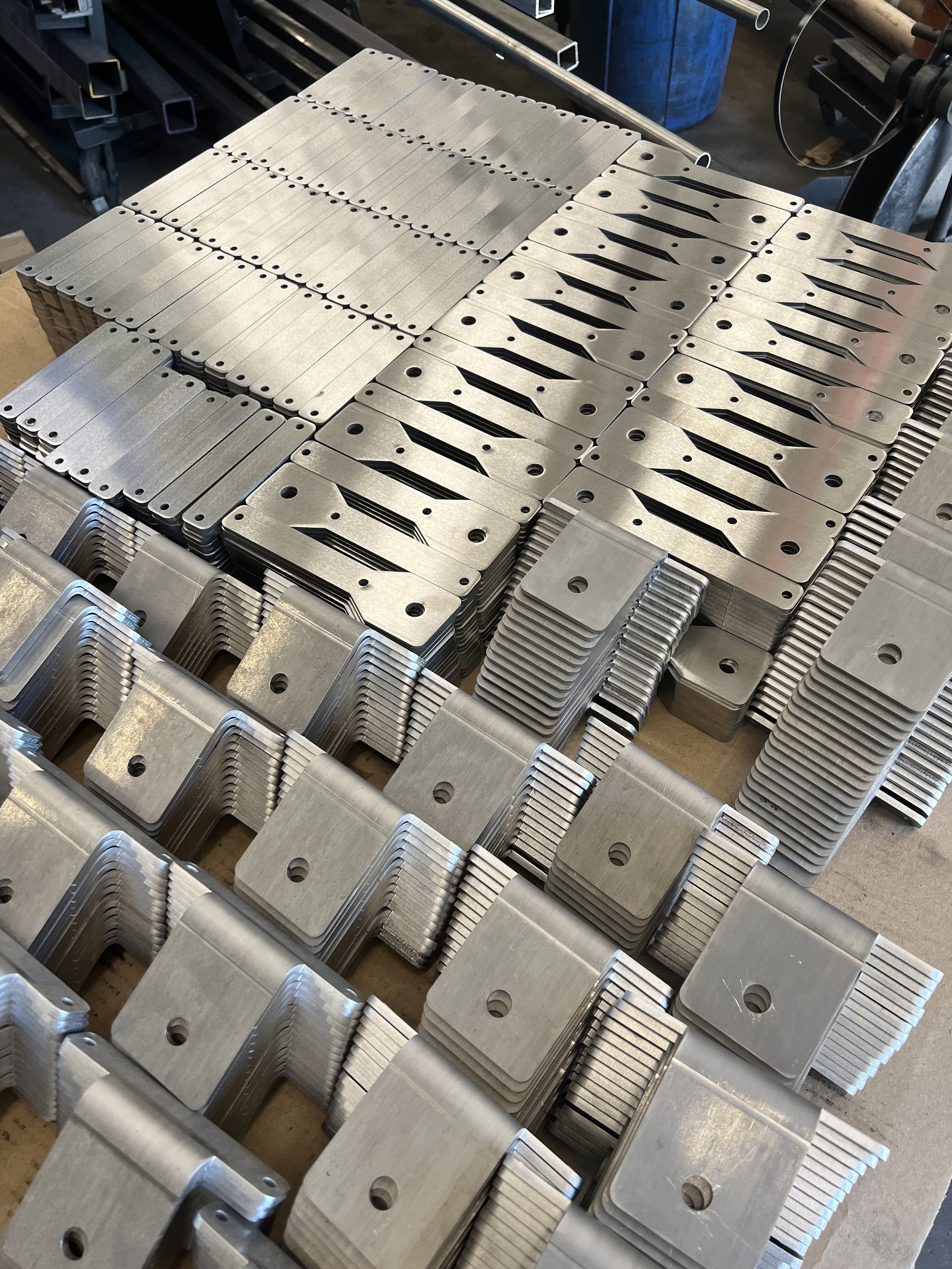

High-Quality Waterjet Cutting Services

Producing Clean Cuts With Exceptional Precision and Flexibility

The CAMM Metals team leverages waterjets in several different ways:

We use them to cut all of our flat sheet metal and plates to feed the fabrication work we handle.

We use these machines to process thick plates and pre-cut shapes and blanks for our CNC machining centers.

We offer waterjet cutting as a service to customers without this capability. We can use our material, or customers can drop ship their own material. Generally, their parts will be cut and ready in three days.

The Benefits of Our Waterjet Cutting Services

No Heat Affected Zone

Waterjet Cutting is a cold process. This service eliminates the need to purchase custom tooling, reducing unnecessary costs for our customers.

Reduced Setup Times

Our team uses the same setup to cut thin sheet metal as we do to cut 6” plates, saving our time valuable time.

Material Variety

Waterjets are capable of cutting a wide variety of materials. We regularly cut:

Steel

Stainless steel

Aluminum

Hastelloy

Brass

Copper

Plastics

Composites

Laminated materials such as carbon fiber

Titanium

Inconel

Waspaloy

The Differences Between Waterjet Cutting and Laser Cutting Services

-

Waterjet and laser cutting methods both offer exceptional precision. However, laser cutting provides a slight edge here, with the ability to achieve even tighter tolerances than waterjet services.

-

Waterjet cutting is a highly flexible tool. Our ability to cut a wide range of materials, including laminated materials and composites, gives waterjet cutting a slight edge over laser cutting.

-

Waterjet has one very significant advantage over laser cutting. Waterjet cutting is a cold process that does not apply heat to the material during the cutting process. As a result, no heat-affected zone is created during waterjet methods. This is particularly important to our customers in the aerospace industry, as our waterjet cutting services do not alter the physical state of the material being cut or cause the material to warp from the heat.

Choosing the Right Method

Whether you choose waterjet or laser cutting services for your products should depend entirely on the end application. There’s no catch-all better solution in this instance, as they both offer excellent results and clean cuts.

Request A Quote for Waterjet Cutting Services

Partner with CAMM Metals for versatile sheet metal fabrication services. We’re your single-source supplier for sheet metal cutting, bending, fabricating, and welding services.